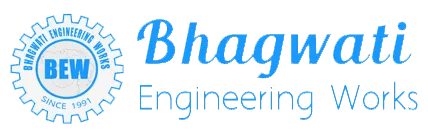

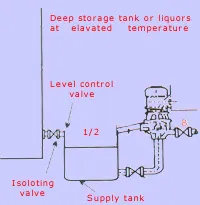

Tank overflow 'D' prevents liquid level rising in pump body and damaging the motor. The lower lip of overflow 'D' should not be more than 1/2" above center of pump overflow.

A vertical suction pipe with non-return valve entering top of tank may be used when liquid is free from suspended solids.

Installation 1

- 1 Fully open valve 'A'

- 2 Allow level of liquid to rise in supply tank up to overflow 'D' level

- 3 Close valve 'B'

- 4 Start pump

- 5 Open valve 'B' gradually for required flow

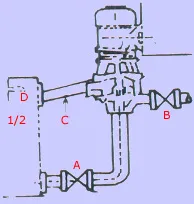

Installation 2

- 1 Close valves 'A' and 'B'

- 2 Open valve 'D' until liquid flows out of 'C'

- 3 Start pump and immediately open valve 'A' fully

- 4 Close valve 'D'

- 5 Open valve 'B' gradually for required flow

Valve 'A' must be at least 1/2

size large in bore than suction pipe

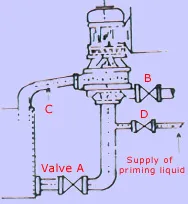

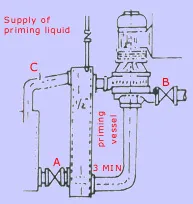

Installation 3

- 1 Close valves 'A' and 'B'

- 2 Open valve 'D'

- 3 Fill priming vessel to overflow 'C'

- 4 Start pump

- 5 Open valves 'A'

- 6 Close valve 'D' and open valve 'B' for flow required

Installation 4

- 1 Close valve 'A' and 'B'

- 2 Fill priming vessel

- 3 Start pump

- 4 Open valve 'A' gradually until fully open

- 5 Open valve 'B' gradually for required flow

Installation 5

- 1 Close valves 'A' and 'B'

- 2 Open valve 'D'

- 3 Fill priming vessel to overflow 'C'

- 4 Start pump

- 5 Open valves 'A'

- 6 Close valve 'D' and open valve 'B' for flow required

Installation & Operation

Application Scenarios:

- Where Low Level priming is not required

- Where Low Level priming is required

- Where priming at all levels is required

- Where priming at all levels is required without re-circulation

- For deep variable head storage tanks

Installation Requirements:

- Straight overflow from pump to supply/priming vessel

- No restrictions (valves etc.)

- Slope down -1 in 20 or more

- Preferably 12" long maximum

- Valves 'A' to be of the free flow type